Product description:

Cross with sorting machine composed of continuous car host, orbit, straight line motor, import table, wave leakage cable, communications systems, power supply system, sorting crossings, barcode scanning decoder composed of equipment such as closed loop system, series cars driven by linear motor, one-way loop operation in vertical direction along the orbit, the condition after import automatic will smooth import sorting machine car, read the code after Saul, database address after the search, a belt of car moves smoothly the discharge to the designated goods a sorting crossings.

Product advantages:

Compact structure, small footprint

Efficient low consumption

High speed, low noise

High cost performance and low failure rate

Product technical parameters:

Main running speed: 0.8-1.8m/s (multi-stage variable frequency adjustable)

Sorting efficiency: 6000-12,000 pieces/hour (double side supply)

Sorting car: standard size L660*W440 mm (non-standard and customizable), standard pitch 500,

Type of disposal: box packing, plastic bag packing, envelope, woven bag and other non-stick, non-ball items (excluding fragile products)

Processing size: Max: L600*W400*H380 mm Min: L100*W60*H2 mm

Processing weight: Max: 15kg Min: 10g (15kg-30kg customizable)

Misclassification rate: ≦0.01%

Sorting breakage rate: ≦0.01%

Bar code recognition rate: ≥ 99.9% (bar code grade B or above)

Machine average noise: ≦70dB

The supply system: the supply system is to realize the efficient and accurate processing of the sorting host, and its function is to automatically measure the physical parameters of the sorting parts and to identify the information, so as to ensure that the parts to be sorted are accurately sent to the high-speed moving sorting car. Shenzhen lisheng technology supply system enables customers to customize the supply system in automatic, semi-automatic or manual modes according to the operating environment.

Host system: the host system is to realize the system sorting the main executive, its function is to carry the sorting information of the objects according to the established logical relationship accurately into the sorting lattice. Shenzhen lisheng science and technology main engine system, using the domestic and foreign mainstream servo direct drive technology and load automatic correction function, millisecond instantaneous start, to ensure that the goods cart accurately center, reduce the sorting error rate.

Next part system: the next part system is the terminal equipment of the sorting system, whose function is to temporarily store the objects sent by the sorting host. At the same time, the information is transmitted to the master control system through the detection and display of the relevant parameters of the entry object, and it has a certain management function. According to the form of sorting goods, the sub-system of shenzhen lisheng technology main engine can provide users with various sorting outlets, such as chute type, bag rack type, cage car type, with/without power grid type, etc.

Control system: the control system is the brain and nerve of the whole sorting processing system. This system comprehensively applies mobile power supply technology, mobile communication technology, field bus, OPC communication, industrial Ethernet communication, PLC servo and frequency conversion technology. Not only will each functional module in the system organically combine to coordinate the work, and the communication machine in the control system can exchange data and management strategies with the upper management system, through which the sorting system becomes an inseparable part of the whole logistics information management system. Shenzhen licheng technology control system adopts the latest type of Siemens PLC, leakage cable, wireless communication terminal and other mainstream equipment.

Software management system:

Sorting control: the corresponding data will be extracted and stored in the database after various message messages sent by PLC are analyzed, and the corresponding sliding slot information of the barcode will be quered in the database and transmitted to the master control PLC.

Printing control: conduct management and control of multiple bar code printers (Ethernet) on the site, and print the construction bag after small parts sorting.

Sorting plan: manage, activate, cancel, and edit the sorting plan to map the destination code into a concrete object chute.

Data query and report: the system sorting data processing, mail sorting path, statistical data query and compilation of related reports (lists and graphs) and data storage management.

Management configuration: to manage various system parameters, configuration (such as sorting mode, prefix of child and mother waybill, the beginning of the package and the number segment of the package), user rights, etc.

SCADA: remote control of field equipment; Fault diagnosis and status display of equipment.

The sorting information system and the sorting control system are integrated into one software and deployed to a PC or server. The software runs automatically without manual operation or intervention. The printing control system is separately deployed to a PC for printing control; The sorting plan system, data query and report system, and management configuration system are integrated into one software and deployed to one PC, which requires manual operation, and SCADA is deployed separately.

Remote diagnostic service

The system adopts the function of remote monitoring and diagnosis, and technicians can carry out fault analysis remotely, which is a quick solution on the spot.

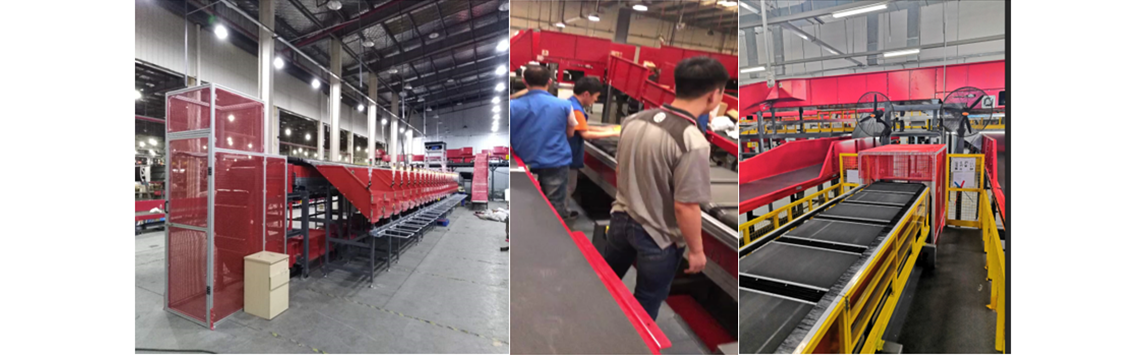

Shenzhen sf-5 and small parts sorting project:

Since the beginning of production on June 1, 2018, it has been running for 273 days till March 1, 2018, with a total sorting quantity of 186,295,200 pieces and a sorting error number of 3,592 pieces, with an error rate of 0.0019%.

The project adopts four vertical lines:

Length of each main line: 29.6 m

Quantity of each trolley: 108

Number of slots per slot: 40

On the way: 8 people on two sides of the bag